CR VAWT wind turbines reimagined - Manufacturing

| HOME | OUR COMMUNITIES | MANUFACTURING | WHY CR VAWTs | EXPERIENCE |

Manufacturing advantages:

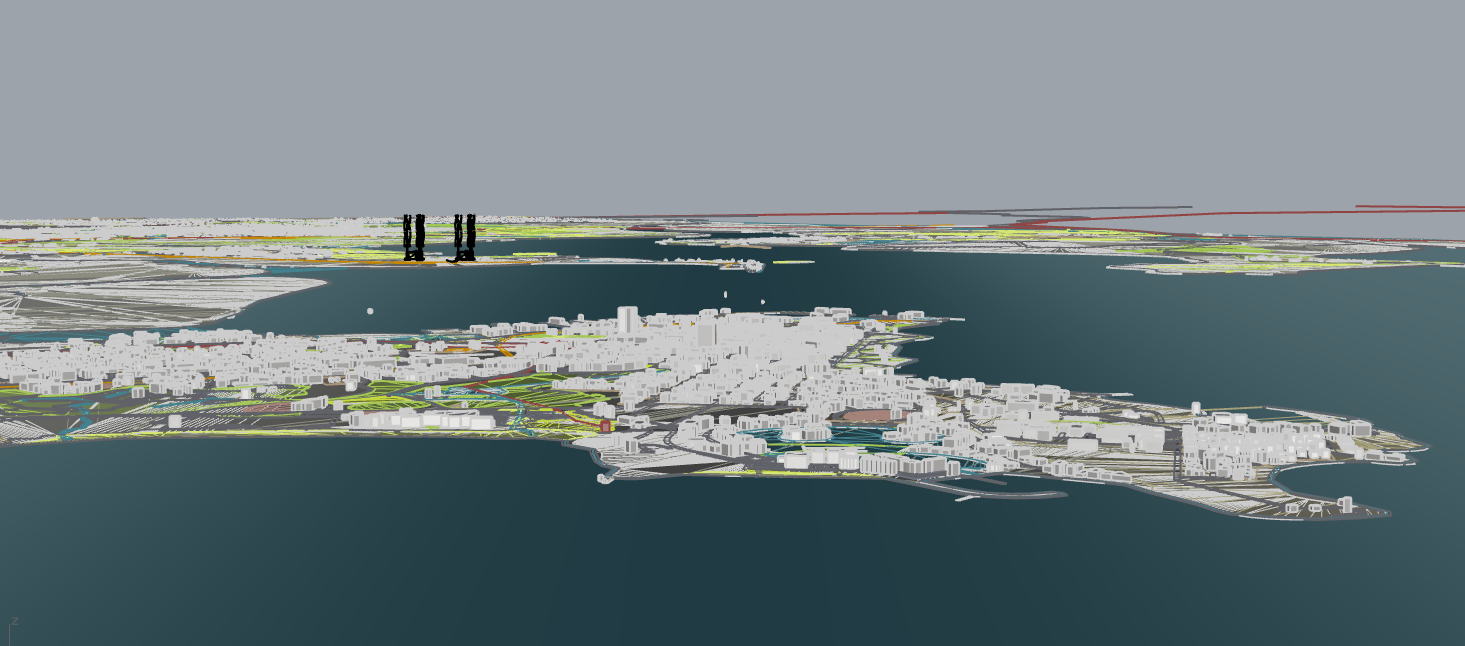

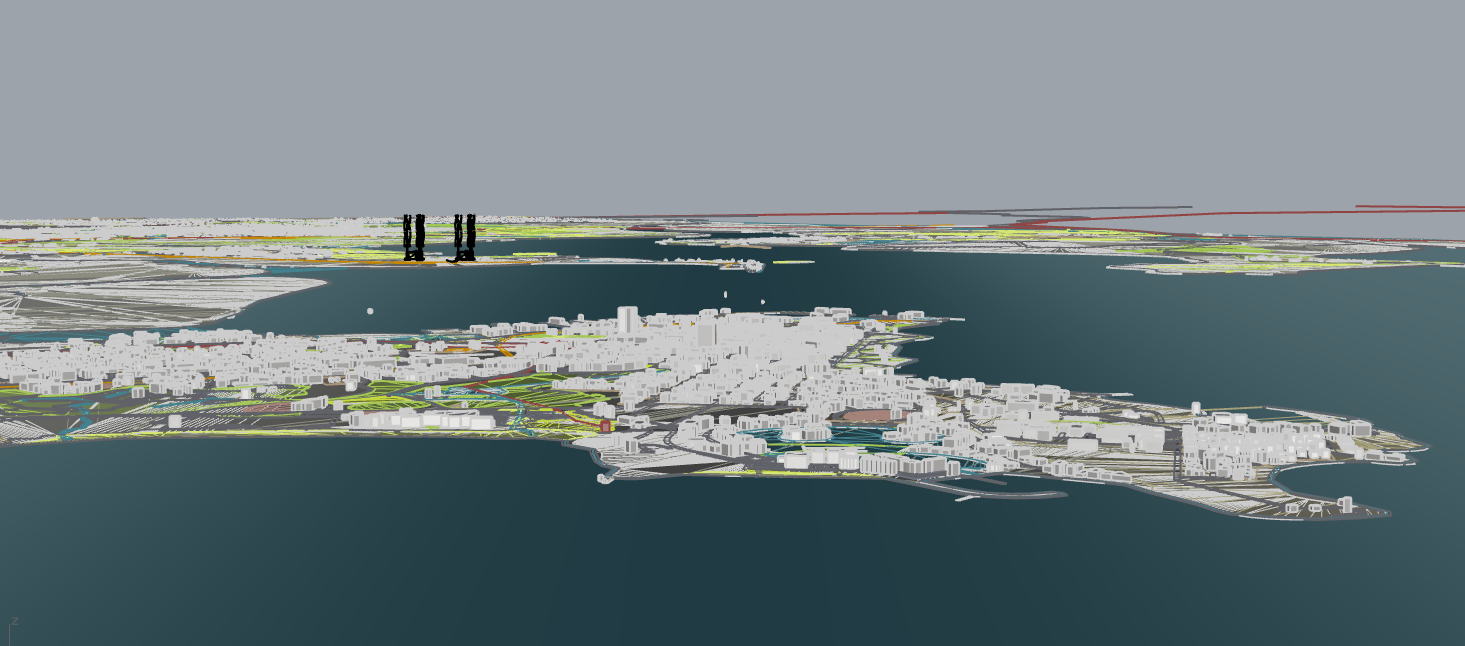

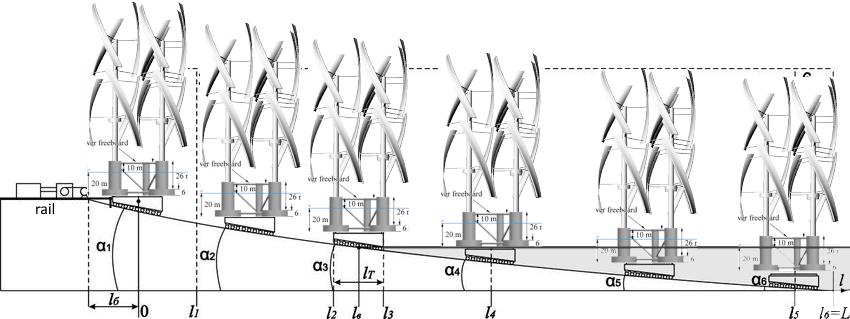

Being able to manufacture all the main components and assemble on-shore in Darwin gives a huge financial advantage to CR VAWT! We can then tow or ship these massive structures globally.

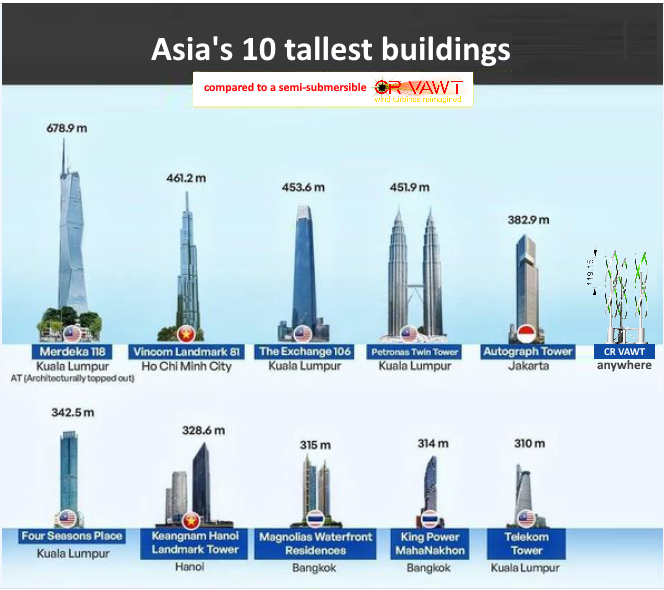

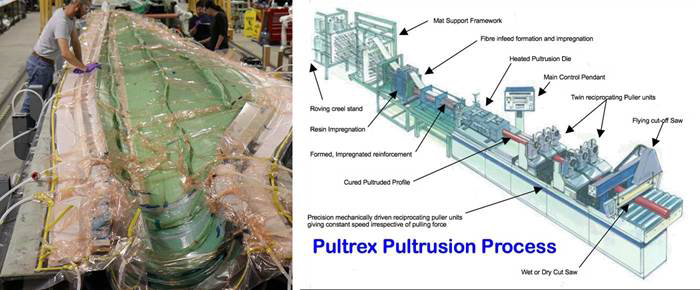

A key cost of wind turbines are

the

blades which account for 25% of HAWT costs as they are very labour intensive

(below left). Because of this complexity MOST HAWT blade failures can be traced

back to a manufacturing error.

Gearboxes: Typically

represent 13% to 15% of wind turbine costs and adds complexity and maintenance

issues. The Farste Drive and CR VAWT doesn’t require any gearboxes.

| copyright crvawt.com 2024 |