CR VAWT wind turbines reimagined - Why

| HOME | OUR COMMUNITIES | MANUFACTURING | WHY CR VAWTs | EXPERIENCE |

According to research developed for the Asian Development Bank; Vertical axis wind turbines are an indispensable type of wind energy technology, which have not yet been fully utilized.

https://www.adb.org/publications/appropriate-technologies-removing-barriers-expansion-renewable-energy-asia#

"Horizontal axis wind turbines (HAWTs)

account for the bulk of grid-connected wind turbines, but are expensive,

gigantic, difficult to install, operate, repair and maintain, and require a

large area of land for their operation. They need fast winds to generate power

that is not available all the time and have to be shut down during strong winds

that are above their “survival speed.” Since they are intermittent sources of

power generation, they consequently require backup generators, and these

generators usually emit carbon dioxide. Given this reality, it could be

concluded that wind turbines are an inappropriate means of power generation, but

it is HAWTs, rather than all wind turbines, that have major negative features,

making them an inappropriate choice for large-scale power generation, despite

their benefits."

"Vertical axis wind turbines (VAWTs) are a solution, but they are not yet widely

used, and their technology needs further development to address their

shortcomings. VAWTs operate with slower wind speeds than the required minimum

speed of HAWTs, and with very fast winds. VAWTs are much cheaper and easier to

build, install, operate, repair and maintain than HAWTs, do not require a large

area of land, and can be installed near each other, in between HAWTs and in

urban areas."

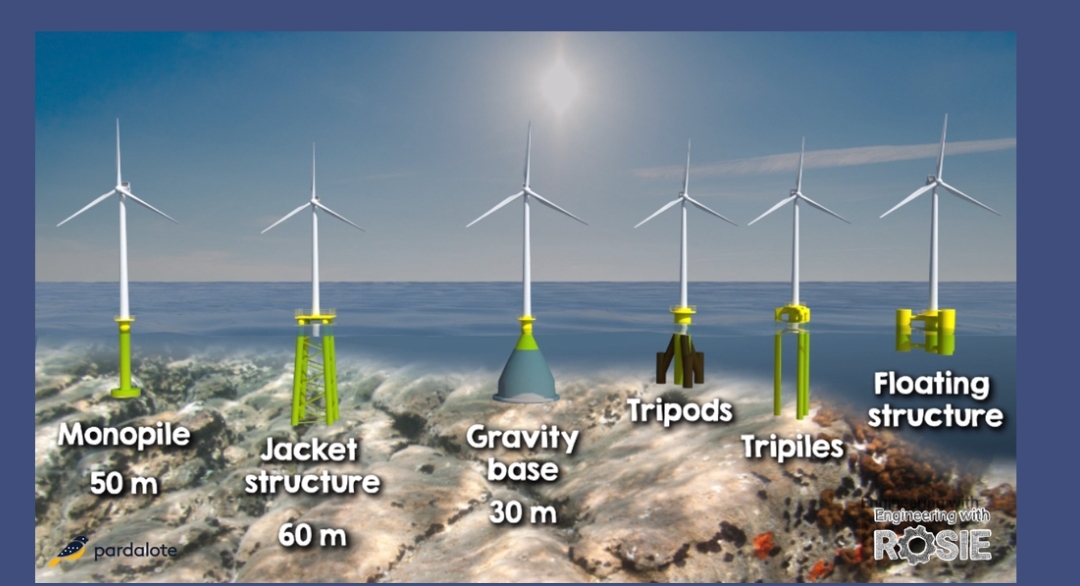

Roughly 80% of the world’s offshore wind

resources are located in waters too deep for regular offshore wind turbines,

according to the Global Wind Energy Council, a forum representing the wind

sector. By investing in floating offshore wind, more renewable power generation

can be harnessed, as the turbines are able to operate in deeper waters where

there is more wind.

“Floating offshore wind technology accesses these strong winds and unlocks the

possibility of building more much-needed clean power,”

We can install 3 CR VAWTs on each semi-submersible which further enhance it's productivity!

Semi-submersible CR VAWT 24MW arrays (below) offer significant advantages over conventional HAWTs!

https://www.weforum.org/agenda/2022/11/offshore-wind-farms-future-renewables/

Why CR VAWTs:

Reduce wildlife mortalities.

Low noise.

Arrays allow high density of turbines near existing infrastructure.

9 x better reliability and longevity than a conventional generator.

Low stress blades in VAWT configuration ensures increased service life and

reliability.

A

CR VAWT will have >double the service life to a HAWT!

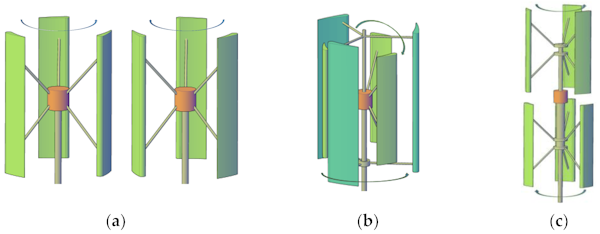

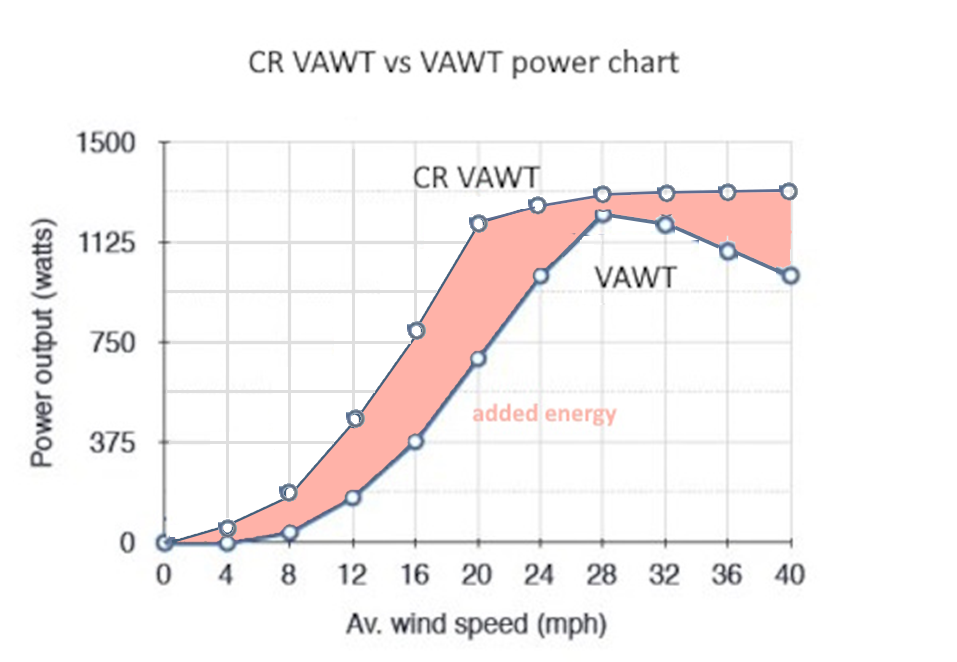

1. The configuration of the CR VAWT

Allows the rotor and stator to rotate in opposite directions, doubling the

actual wind speed and energy output without the need for a gearbox. This feature

allows the CR VAWT to have a world leading turbine efficiency of 56% (20% more

than HAWTs) and generator efficiency of 98%

Research shows that there are a few characteristics and advantages of vertical

axis wind turbines that make them perfect choices for certain geographical

conditions and wind energy applications.

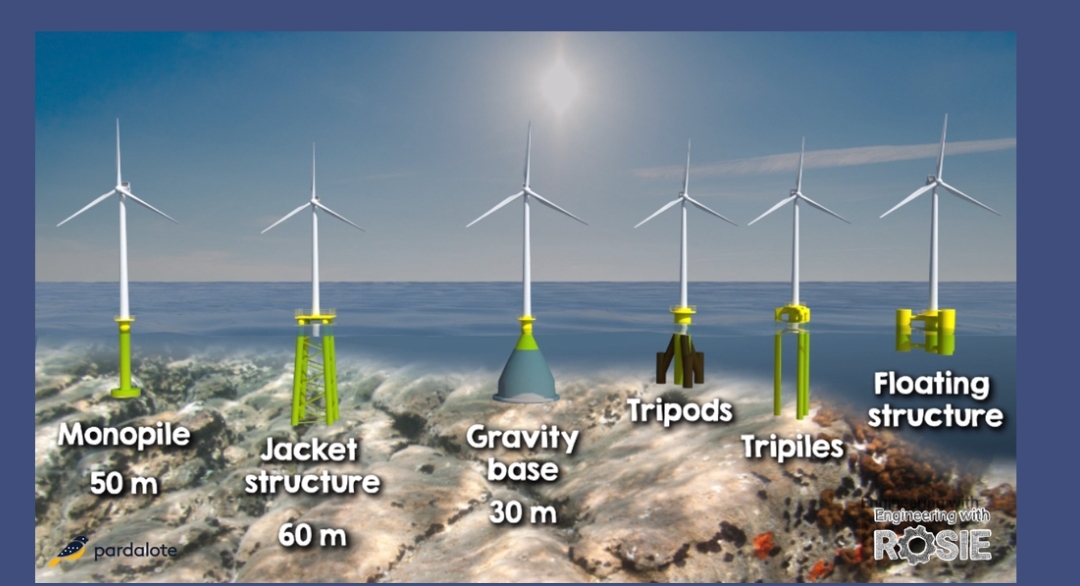

Four different CR VAWT configurations (above)

2. Omnidirectional nature of the Rotor

Vertical axis wind turbines can pick up wind coming from any direction.

Horizontal axis wind turbines need to face the direction of the wind to operate,

and rely on a mechanical yaw system to orientate the rotor in order to capture

wind.

Due to this difference in operation mechanism, vertical axis wind turbines can

be used to generate power even in unstable weather conditions such as turbulent,

gusty wind. They function well in city, mountain and coastal areas.

3. Optimal land use

In a horizontal axis wind turbine farm, the general rule-of-thumb for spacing is

to place the turbines 5 diameters apart across the wind, and about 10 diameters

apart extending downwind. This is to avoid disruption of air flow and reduction

in wind speed caused by one turbine to another, which affects the power output

of neighboring units.

Compared to horizontal axis wind turbines, vertical axis wind turbines can be

grouped closer together in a wind power plant. This is because vertical axis

wind turbines function well in turbulent wind. They are generally spaced 4 to 6

diameters apart.

Closer spacing would allow a wind power plant to capture more energy per square

meter of land. Generally speaking, a single vertical axis wind turbine is not as

energy-efficient as an individual horizontal axis wind turbine. However, a group

of closely-spaced vertical axis wind turbines have the potential to generate as

much as 10 times more power per unit of land compared to a group of

widely-spaced horizontal axis wind turbines.

This also applies to underutilised land in transmission corridors and in

suburbia. Horizontal axis wind turbines requires a large area of land to allow

it a 360 degree turning area. Whereas vertical axis wind turbines can be placed

adjacent to buildings, trees or another turbine.

4. Lower Starting Wind Speed

Vertical axis wind turbines have a lower starting wind speed compared to the

horizontal axis models. The necessary starting wind speed for a typical vertical

axis wind turbine is 2 to 3 m/s. This allows vertical axis wind turbines to

generate electricity even when incoming wind is relatively weaker. Although the

amount of electricity generated at lower wind speeds is small, it makes a lot of

energy available when other wind turbines are not able to harvest at all!

5. Lower Environmental Harm

Generally smaller, the size of vertical axis wind turbines brings along a few

advantages, one of which being low environmental harm. The blades are easier to

spot for birds and other flying animals, decreasing the chance of animal

casualty.

Vertical axis wind turbines spin more slowly, thus operate with quieter noise

emission, so they do not disturb people at work or in residential neighborhoods.

6. Easier Installation and Maintenance

The smaller size of vertical axis wind turbines makes them easier to transport,

set up, and maintain. For example, all parts of one 12kW turbine can be

delivered with a single truck with a 6-meter long storage space. Maintenance

workers do not have to climb as high to reach parts of the turbine because the

major components, such as the generators, are built closer to the ground. Farste

Drives have 9 x better reliability and longevity than a conventional generator.

Low stress blades in VAWT configuration ensures increased service life and

reliability. CR VAWT will have double the service life to a HAWT =less waste and

$$ savings!

7. Less Restricted Installation

Being safer to wildlife and quieter than horizontal axis wind turbines our

turbines can be can be erected close to dwellings and existing infrastructure,

even integrated into lighting poles/towers, telecommunication towers and

neighborhood batteries. And mounted on skids that can be sited on existing

buildings, or where soil conditions won’t allow standard foundations. Solar

needs vast amounts of land and HAWTs need to be located away from populated

areas.

Rather than spend $Billions constructing transmission lines to reach isolated

wind and solar farms we can site CR VAWTs in transmission corridors and on

existing buildings.

Off-shore CR VAWT wind farms near population centres offer the lowest infrastructure cost, the lowest resources use, the lowest visual impact and the least harm to all of earth's creatures!

8. Striking Representation

The modern geometrical designs of vertical axis wind turbines allow them to

operate with elegance and create smooth visual flow. Their appearance is

complementary to buildings, campuses, and parks. Utilising wind power to

generate electricity, they also speak directly about the sustainable values of

an organization or community with strong visual impressions.

9. Generators

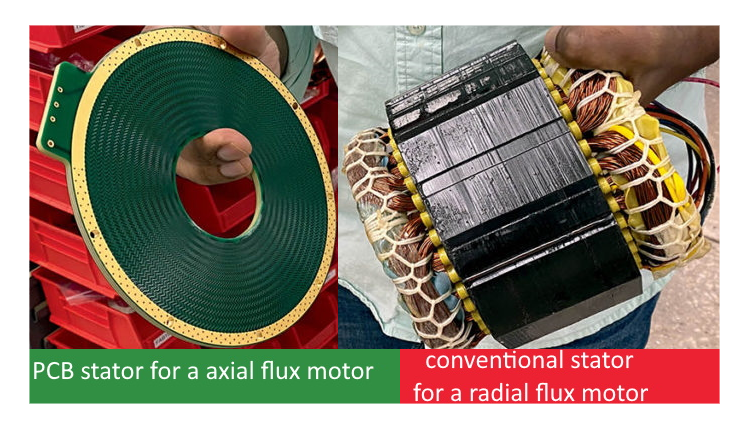

CR VAWT have licenced the Farste Drive (image below) TOROID PCB RADAX electric

motor/generator to provide the generator. The Farste Drive has no copper

windings as per a traditional electric motor; instead uses multi-layered Printed

Circuit Boards (PCBs) that replicate the properties of copper windings.

| copyright NTWTF.com 2024 |